Making the Spirit of Indiana

This is a compilation of behind the scene photos and videos that documents the production of Natella’s latest monument titled The Spirit of Indiana. Through these photos and videos we enter the creative world of process and method in Natella’s studio, while watching the raw material take form.

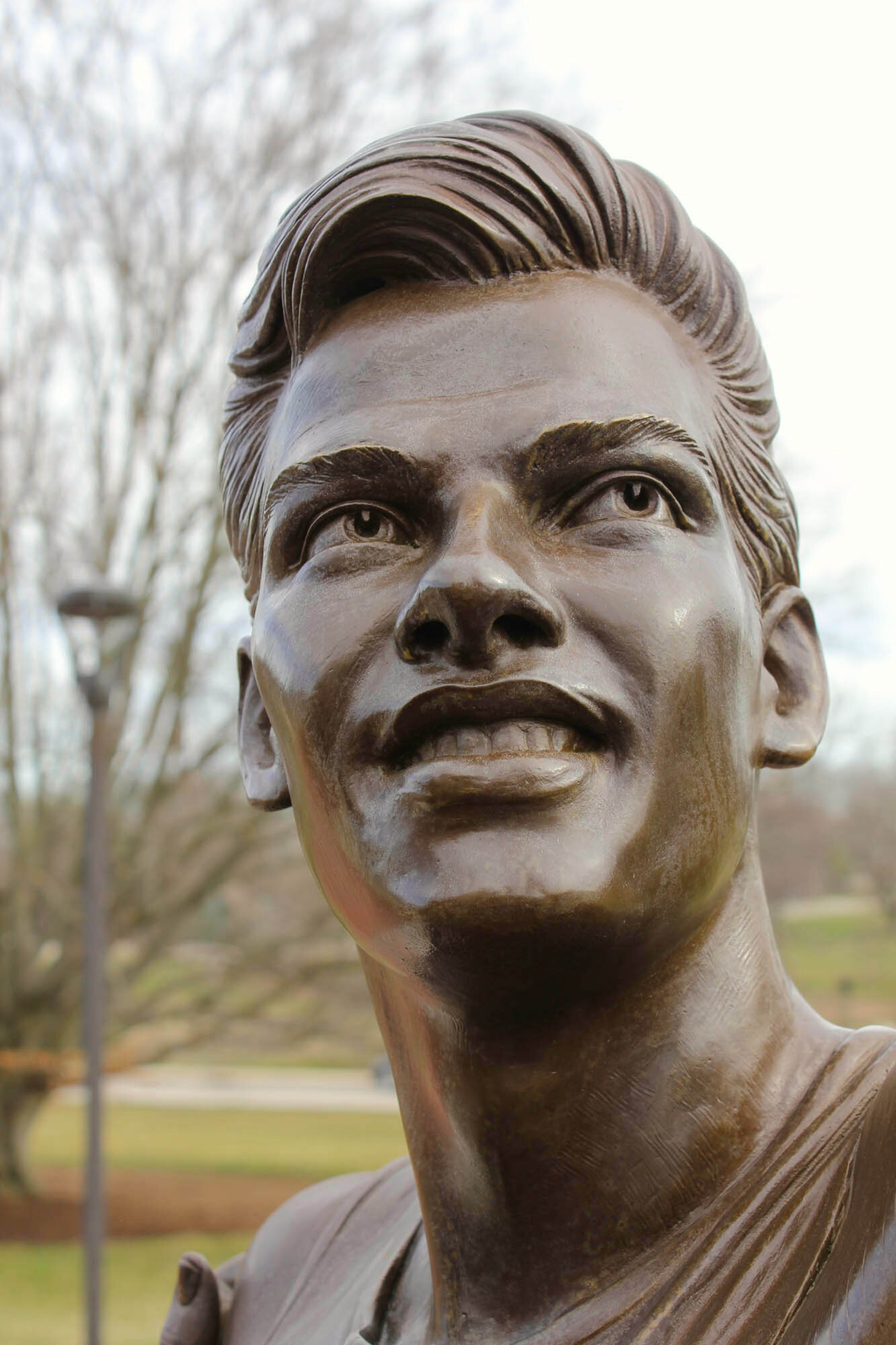

Sculpting the Athletes

The first step in creating this monument was modeling the figures in clay. Each athlete was modeled from direct observation and photos. These clay figures capture not only the unique body types, but also the individual portraits, which represents the diversity in IU’s Student Athletics.

Enlarging the Figures

Once the figures are sculpted life size from clay, they are digitally scanned and milled 8ft tall in polyester foam. The foam parts are assembled and coated with clay to re-introduce details that are lost in the enlargement process.

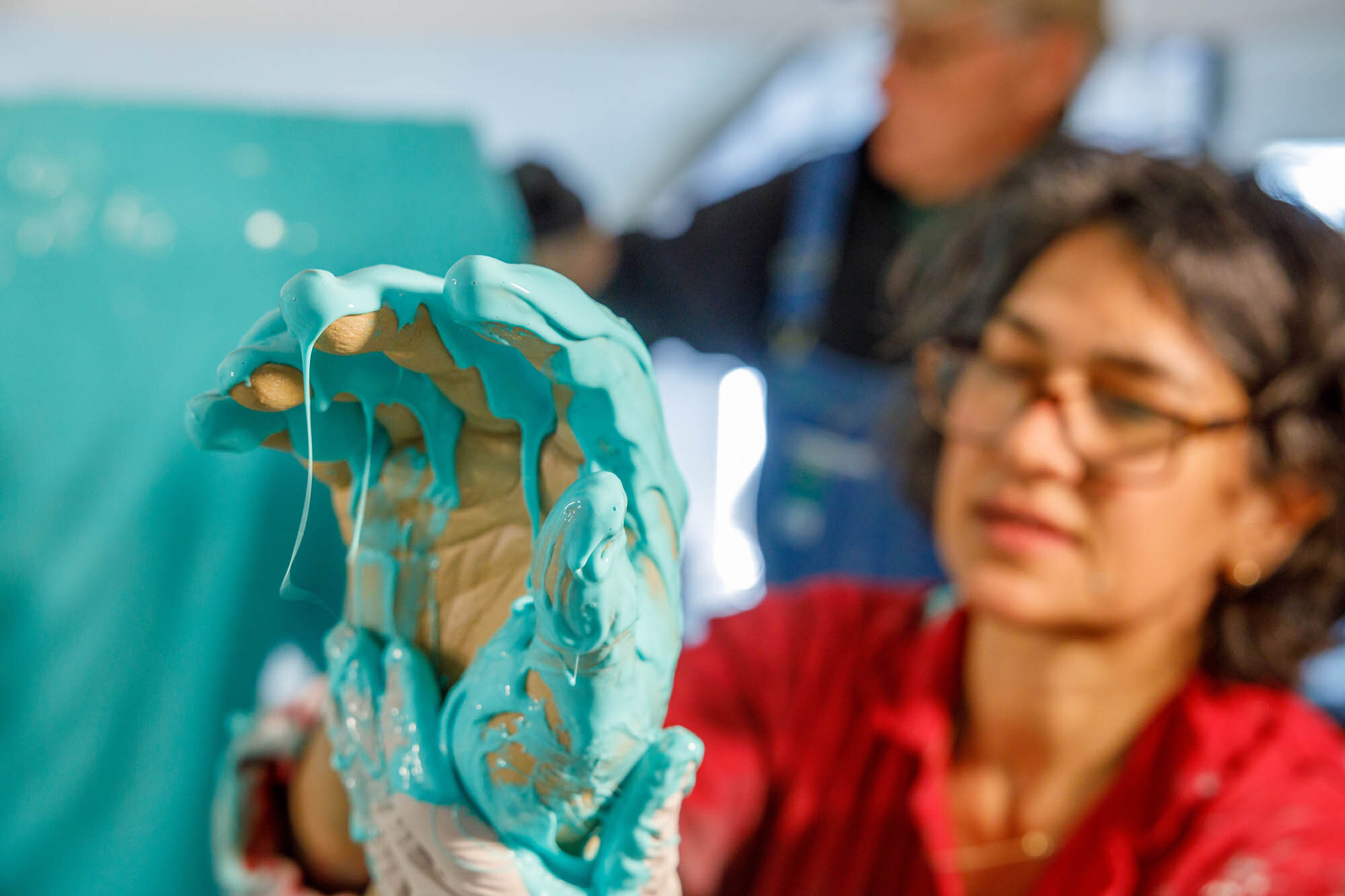

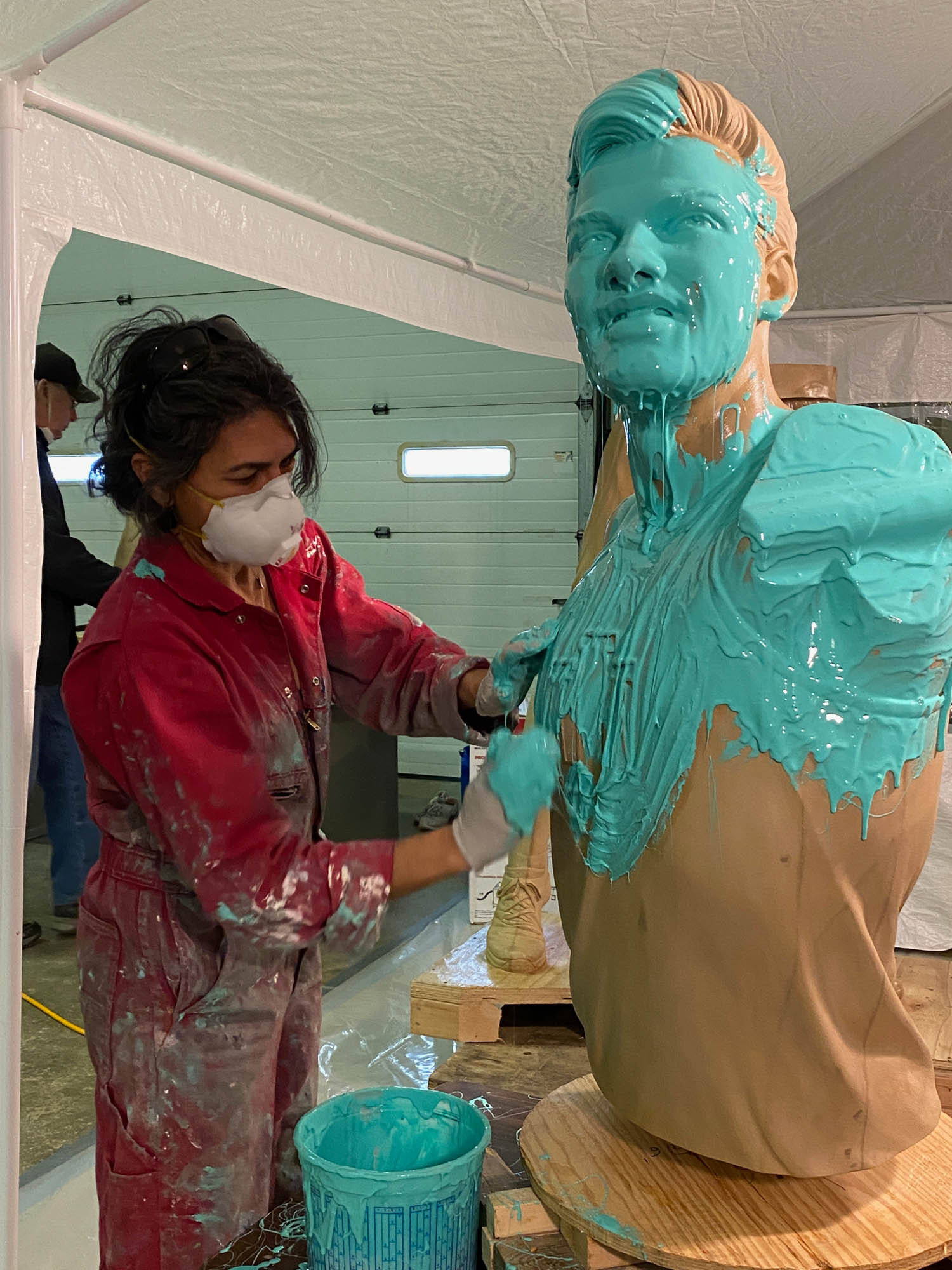

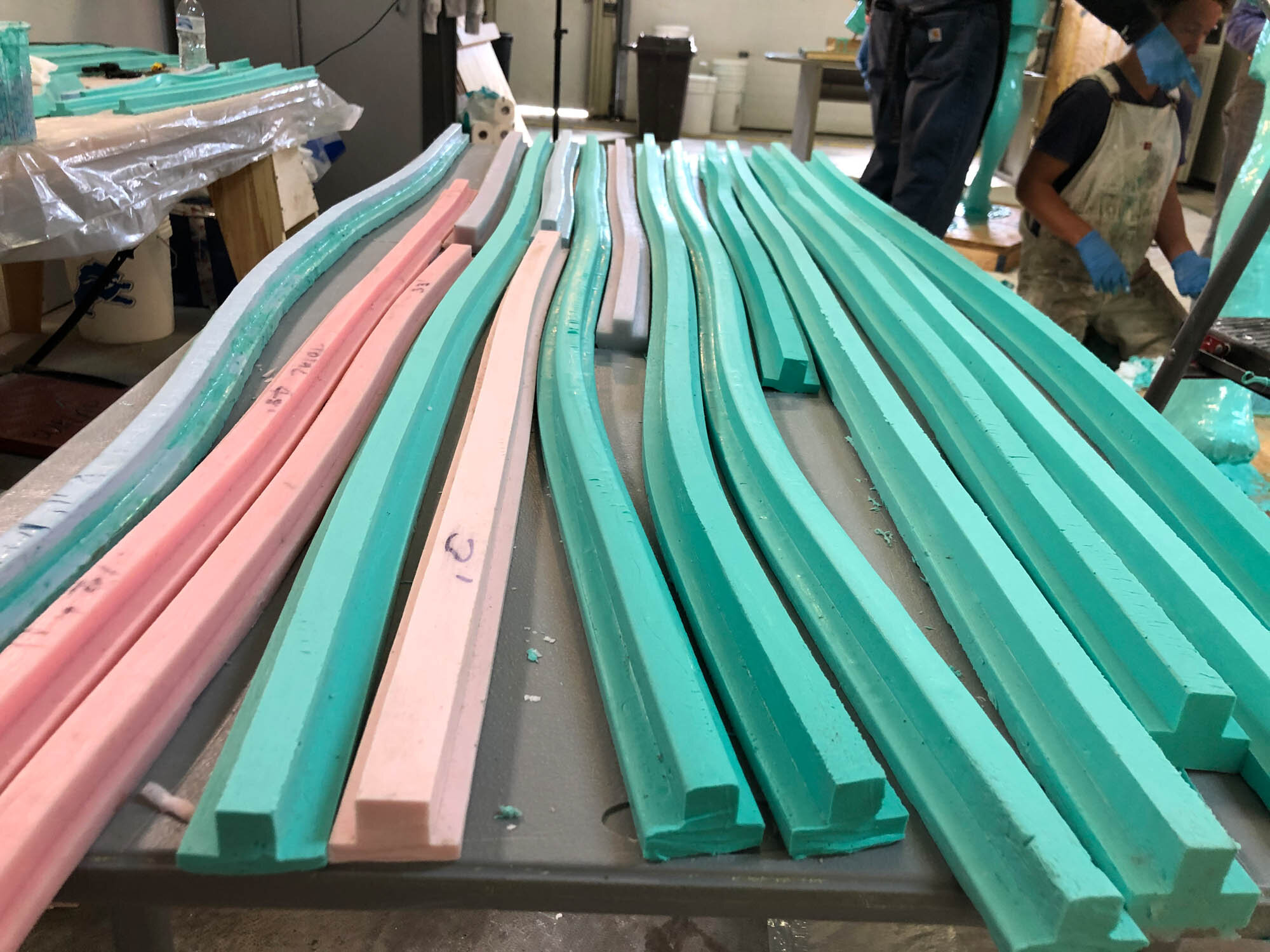

Building the Rubber Mold

At this stage the details of the large figures have been sculpted and the mold making process begins. This involves coating the figures in layers of rubber to get an impression of the original form.

Building the Mother Mold

After the rubber mold is completed, a hard exterior mold is created out of plaster and reinforced with metal tubing to make sure the rubber mold keeps its shape.

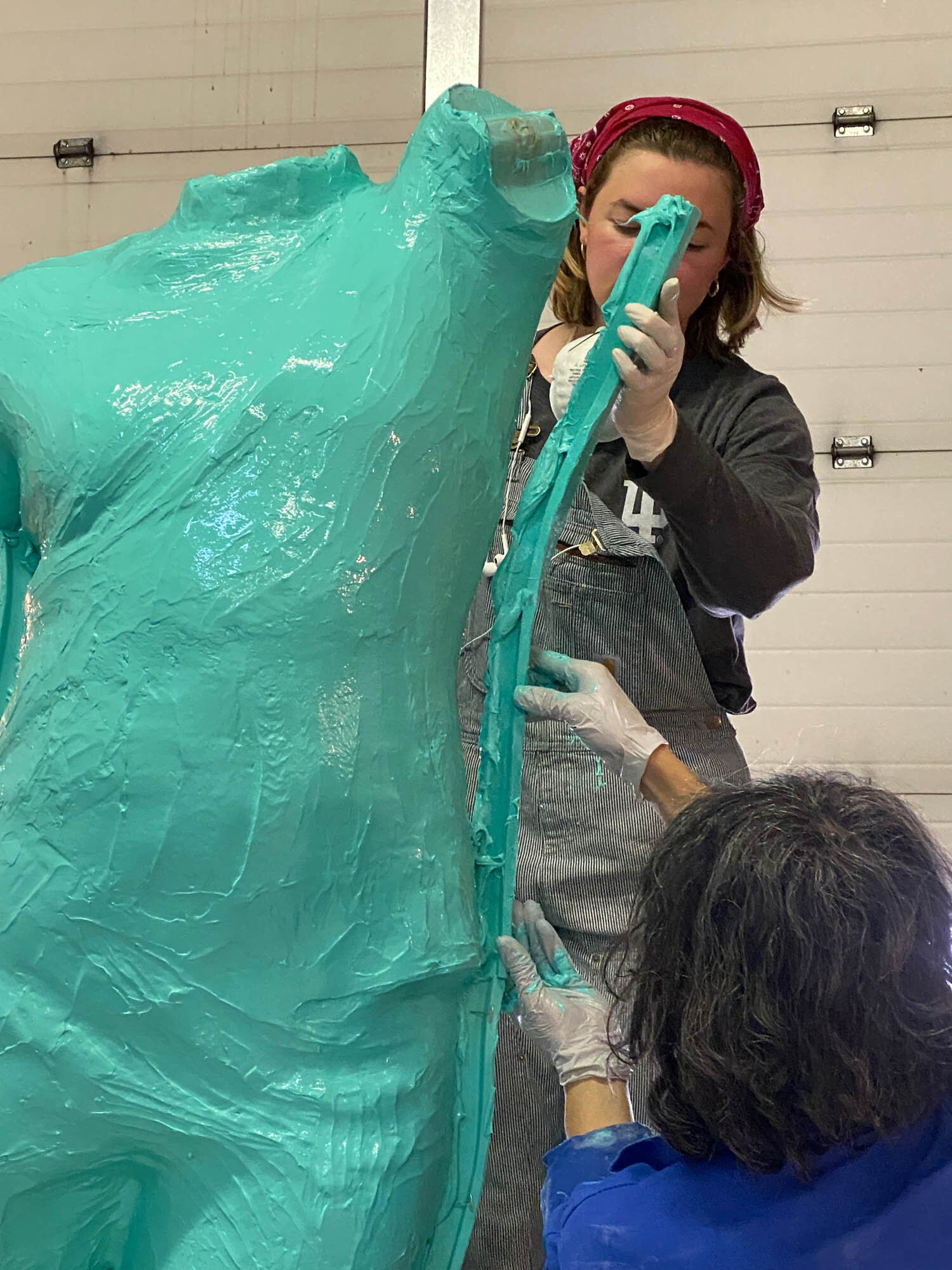

Removing Rubber & Mother Molds

When the molds are finally finished it is time to open them up and remove the clay figures inside, leaving a negative impression of the original form. These molds are then crated and shipped to Bollinger Art Foundry in Arizona where they are cast in bronze.

Lost-wax Process

The Lost-wax Process is an ancient technique in which a wax positive of the sculpture is made from the mold, which will then be invested, burned out, and cast in bronze.

Once the molds arrive at the art foundry, a wax replica of the original clay is produced by pouring hot wax inside the molds. Next, the wax sculpture parts are removed from the mold, the wax dressers attach a sort of plumbing system—called a sprue system—made of wax, that will allow the melted wax to drain out of the investment, and channel the molten metal as it is poured in. For more on this process check out Tuck Langland’s book From Clay to Bronze.

After the spruce system is attached the wax is ready to be dipped in the investment—a compound called ceramic shell—to form a heat resistant mold.

Bronze Pour

Once the ceramic shell mold is fired in a kiln, all the wax has melted away through the sprue system leaving a clean investment. Next, molten bronze is poured into the investment mold through the sprue system and the metal takes the shape of the original forms. Once the metal has cooled, the investment is broken leaving the bronze positives. The casted bronze parts can now be assembled and finished.

Bronze Assembly & Chasing

The cast bronze parts can now be welded together and assembled over a steel armature that is engineered for structural integrity and safety. After welding the surface is chased to eliminate weld beads and surface imperfections.

Engineering renderings of steel Armature

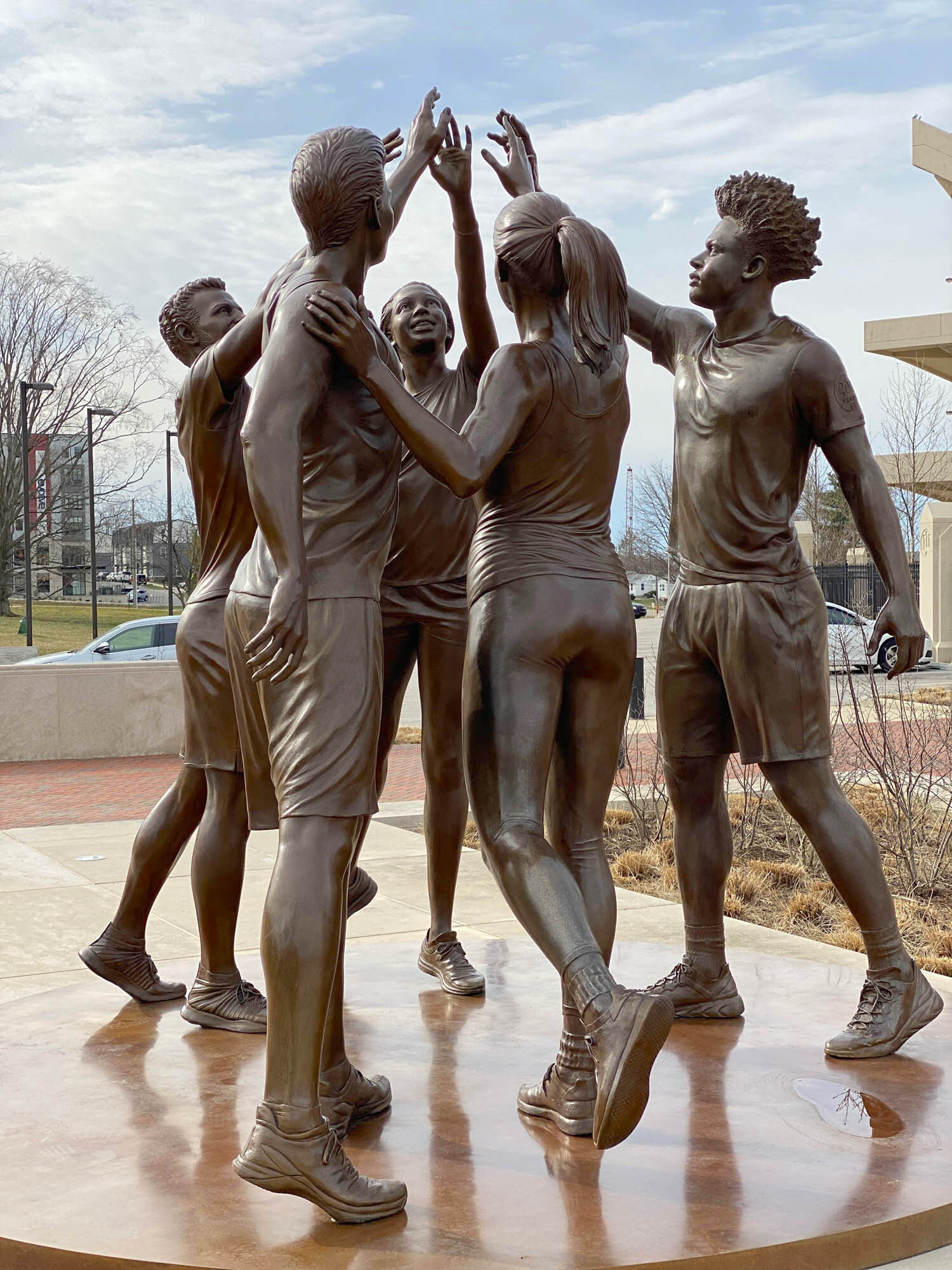

Final Bronze Monument at Miller Plaza

On March 10th, 2021 The Spirit of Indiana was installed on the south end of Memorial Stadium at IU Bloomington. You can find press release for this monument on Sports Illustrated, IU Varsity Club, ABC57 News, and others.